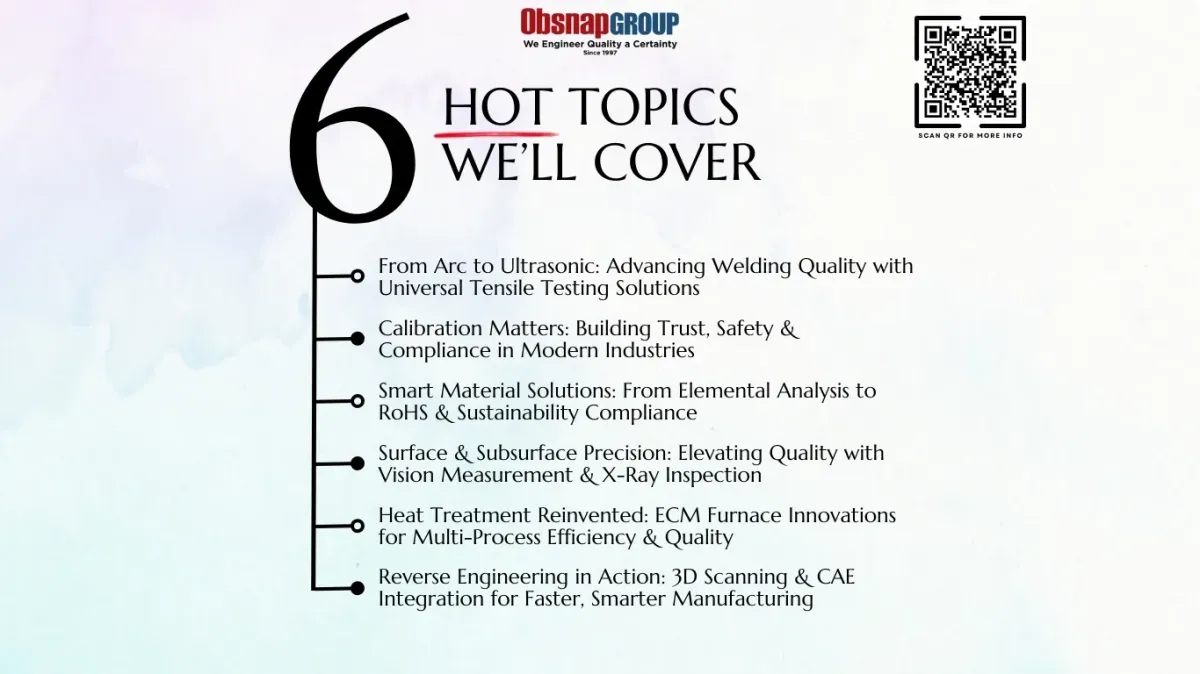

Seminar

From Physical Sample to Production Line: Integrated Workflow of Testing, Reverse Engineering & QC

Discover the latest technologies, insights and applications shaping industries and education for tomorrow.

Date: 5 February 2026

Venue: GENO Hotel, Shah Alam

Time: 8:30 am - 5:30 pm

Bonus For Attendees

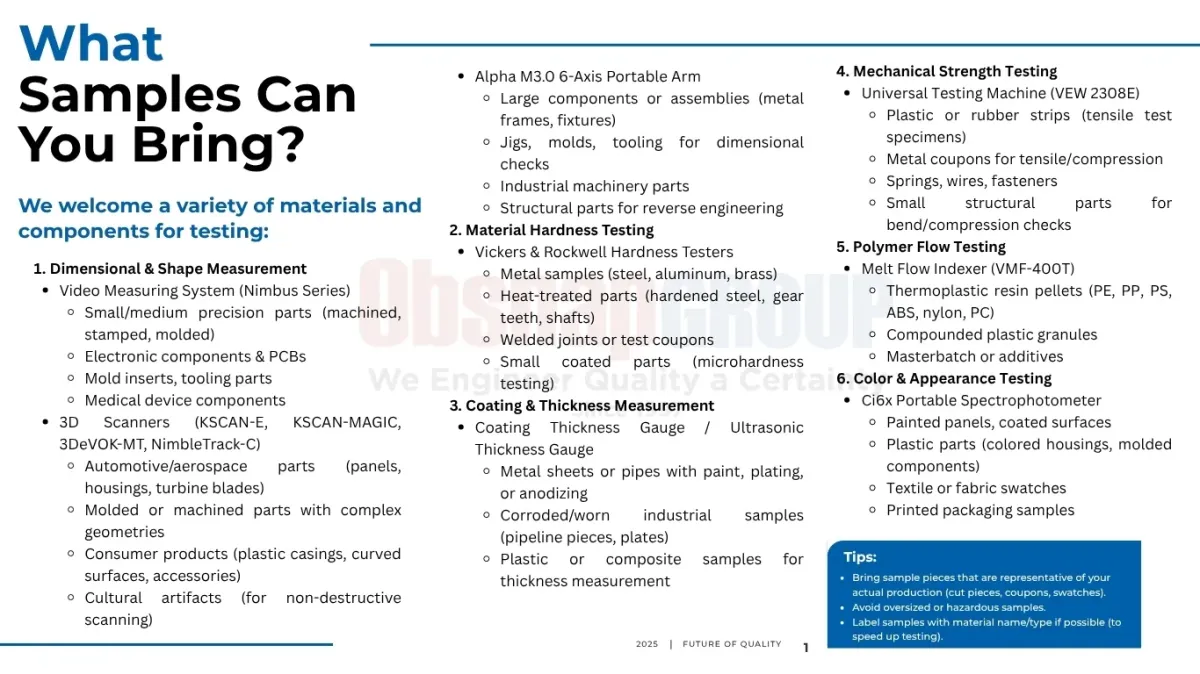

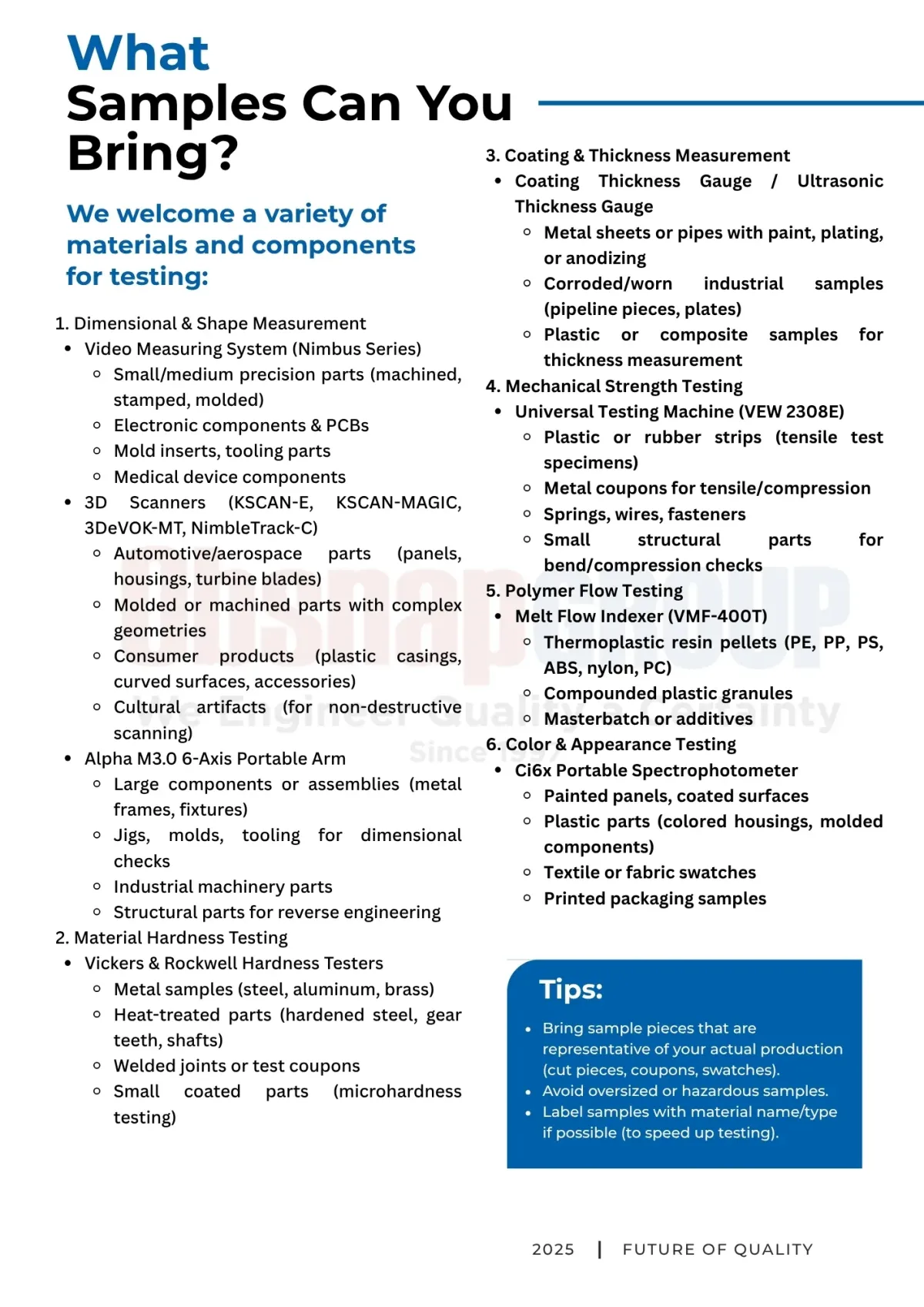

Bring your sample and get it tested using advanced equipment during the seminar

Complimentary TWO testing for all participants!

(Contact us for specific requirements)

Why This Seminar Matters

Global manufacturing and education sectors are facing

tighter quality standards, rising compliance costs, and the demand for skilled talent.

The companies that thrive are those that invest in knowledge and innovation today.

This one-day seminar brings together

industry experts, thought leaders, and practitioners

to share real-world solutions in quality assurance, material testing,

and compliance.

If you want your company to stay competitive, you cannot afford to miss this.

What You'll Gain

Knowledge, strategies, and connections that move you forward.

Hands-on Knowledge

Live demonstrations of the latest testing equipment.

Experience FREE TWO sample testing & measurement

Bring your own sample

Networking Opportunities

Connect with peers from automotive, plastics, and education.

Claimable under HRD Corp

Certification

Participants receive E-certificate by email

Certification

Participants receive E-certificate by email

Pricing & Packages

Early Bird (First 50 pax):

RM299

Standard Price:

RM349

Group Bundle (Max 3 pax):

15% OFF for 2nd & 3rd participant

Note: All prices HRD claimable

Who Should Attend

This seminar is designed for professionals, leaders, and innovators ready to stay ahead.

Qa & Qc Professionals

manufacturing & product managers

r&d and Product Development Teams

lab managers & technician

industrial leaders & business owners

Education & Training Institutions

Plastic & Packaging Producers

Precision Engineering Firms

Education & Training Institutions

Why You Can’t Miss This Seminar

Discover how this topic shapes industries, drives innovation, and impacts your future.

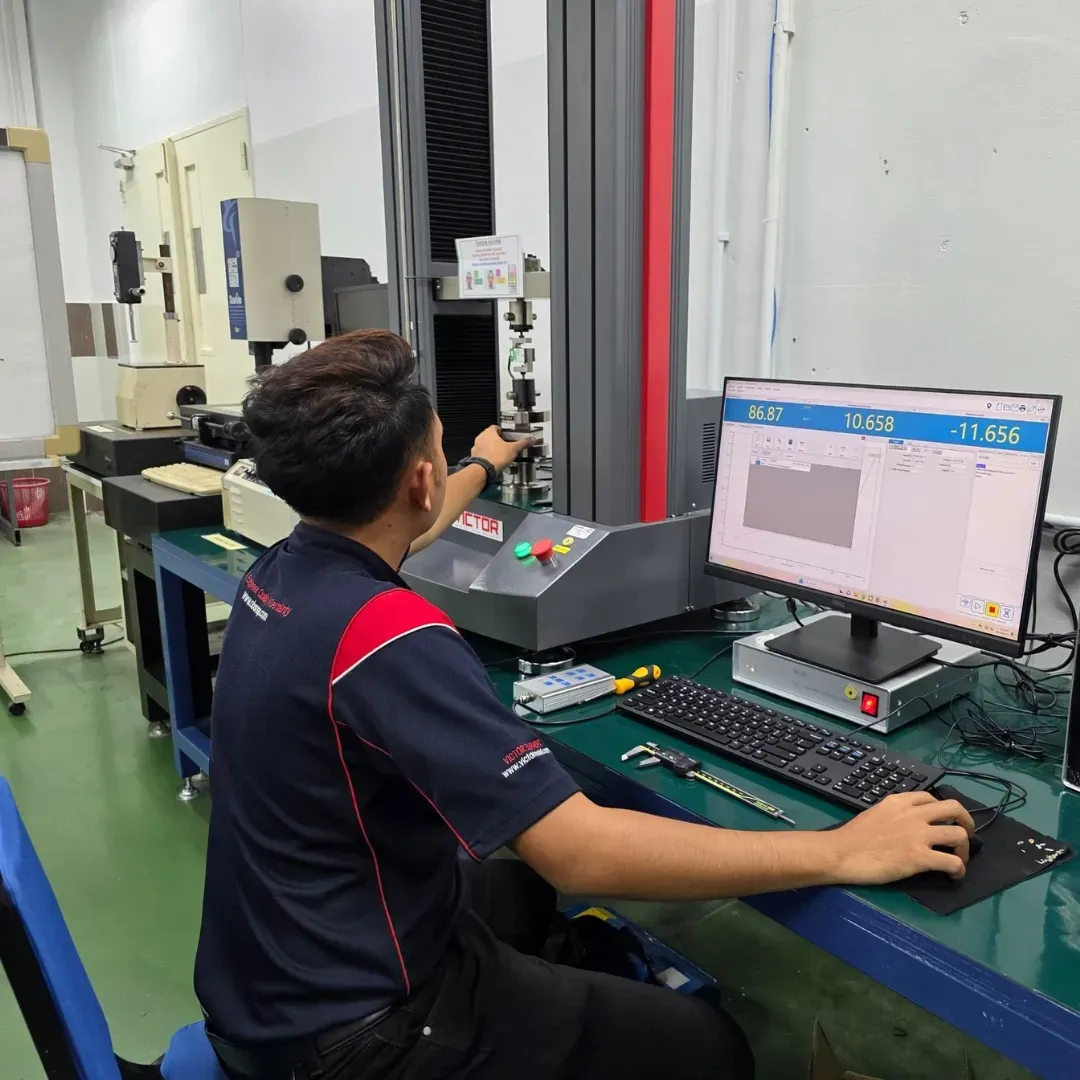

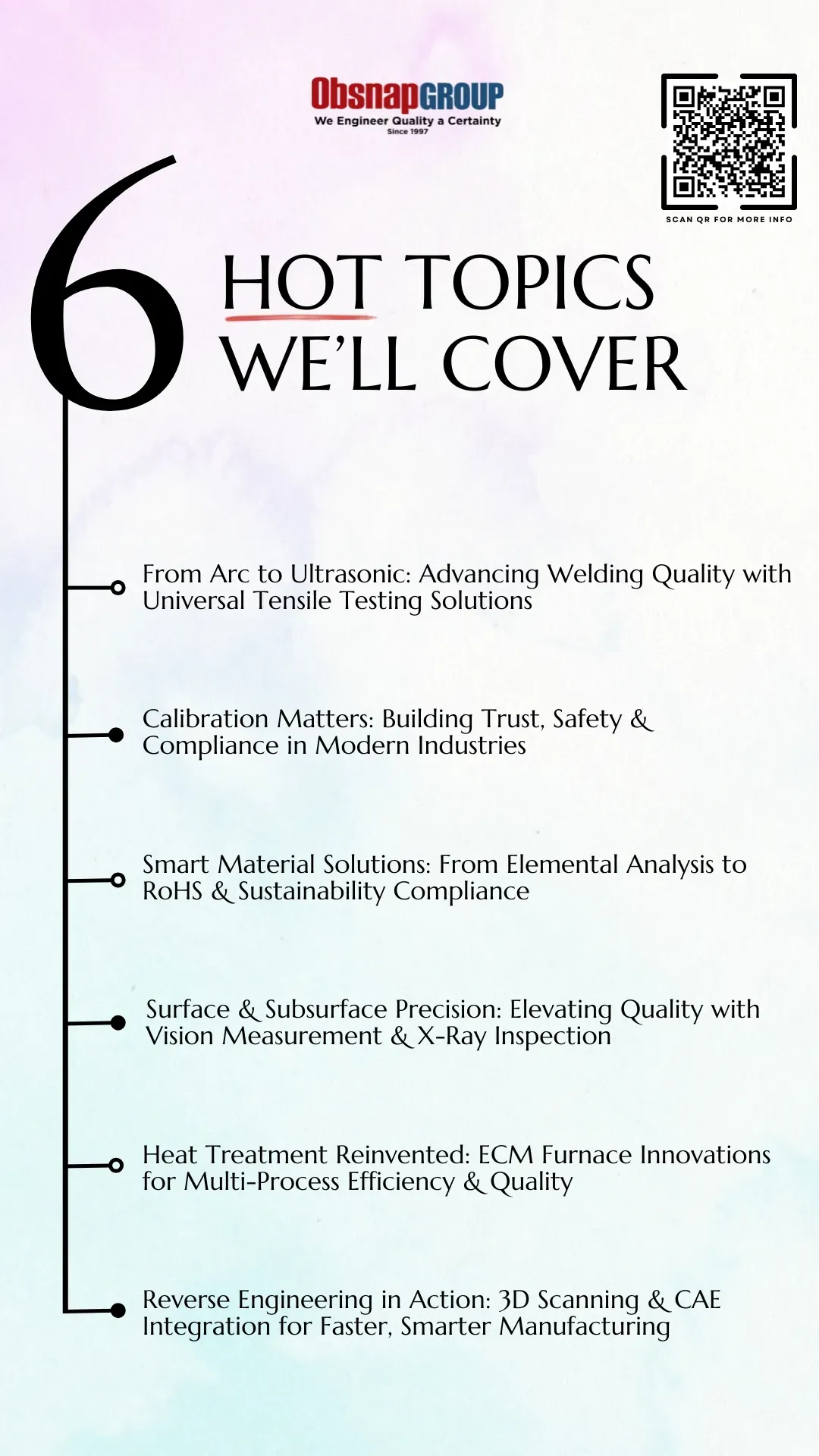

From Arc to Ultrasonic: Advancing Welding Quality with Universal Tensile Testing Solutions

1. Assured Weld Quality & Reliability

Verify that every weld or joint can withstand real-world loads, reducing risk of failures in critical applications like automotive and aerospace.

2. Standards Compliance & Global Credibility

Testing aligned with ASTM, ISO, and other international standards ensures products are accepted in global markets and by regulators.

3. Cost Savings in R&D and QA

Early weld coupon testing and process validation prevent costly redesigns, warranty claims, or production scrap.

4. Versatility Across Materials & Processes

One system supports metals, plastics, and composites, enabling comparative benchmarking for traditional and advanced welding methods.

5. Future-Ready Testing Solutions

As new welding technologies emerge (laser, ultrasonic, additive manufacturing), universal tensile testing remains the foundation for verification.

Calibration Matters: Building Trust, Safety & Compliance in Modern Industries

1. Gain Expert Insights on Calibration Best Practices

Learn directly from industry professionals about the latest standards, traceability requirements, and uncertainty management, helping you enhance your organization’s measurement accuracy and reliability.

2. Ensure Compliance with ISO & Regulatory Standards

Understand how proper calibration supports compliance with ISO/IEC 17025, ISO 9001, and other key regulations, and how to prepare confidently for audits and certifications.

3. Strengthen Safety Across Operations

Discover how accurate instruments prevent failures, improve safety performance, and protect people, assets, and the environment in high-risk industries.

4. Explore Digital Trends & Smart Calibration

Stay ahead with insights on modern calibration technologies, digital recordkeeping, IoT integration, and predictive maintenance, transforming your lab or plant into a future-ready facility.

Smart Material Solutions: From Elemental Analysis to RoHS & Sustainability Compliance

1. Master Smart Material Solutions

Learn how advanced elemental analysis ensures product quality and compliance.

2. Stay Ahead of Regulations

Gain insights into RoHS, sustainability, and global compliance requirements.

3. Boost Market Advantage

Understand how compliance and smart material strategies strengthen customer trust and competitiveness.

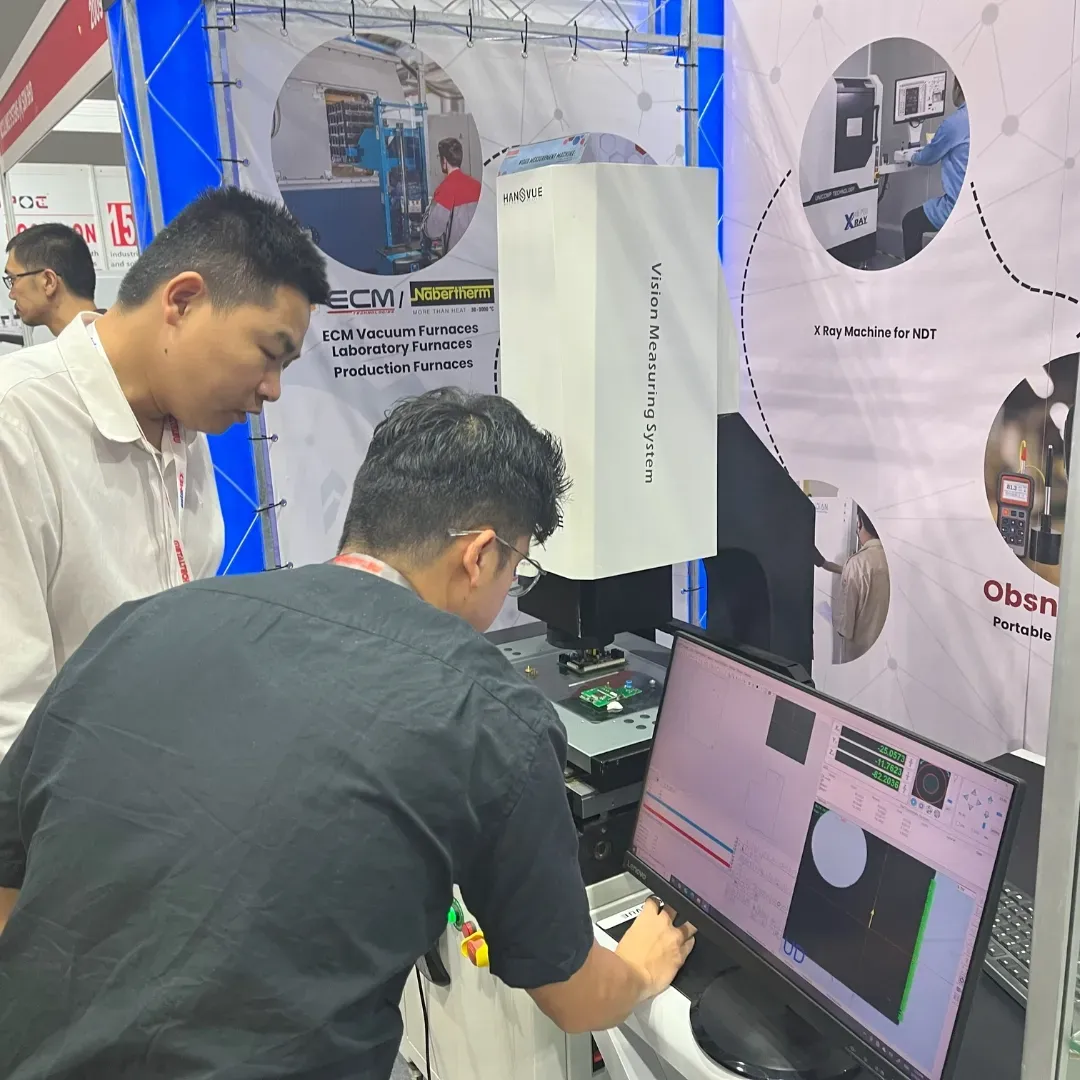

Surface & Subsurface Precision: Elevating Quality with Vision Measurement & X-Ray Inspection

1. Comprehensive Quality Assurance

Vision measurement ensures precise detection of surface dimensions and defects, while X-ray inspection uncovers hidden flaws beneath the surface.

2. Enhanced Reliability & Safety

Identifying both visible and internal defects improves product reliability, safety, and compliance with stringent industry standards.

3. Optimized Manufacturing Efficiency

Early defect detection reduces rework, minimizes waste, and streamlines production for higher overall efficiency.

Heat Treatment Reinvented: ECM Furnace Innovations for Multi-Process Efficiency & Quality

1. Multi-Process Capability

ECM furnaces integrate various heat treatment processes in a single system, reducing handling and production time.

2. Consistent Quality & Precision

Advanced controls ensure uniform treatment results, improving product reliability and meeting strict industry standards.

3. Efficiency & Sustainability

Optimized energy use and reduced emissions deliver cost savings while supporting greener manufacturing practices.

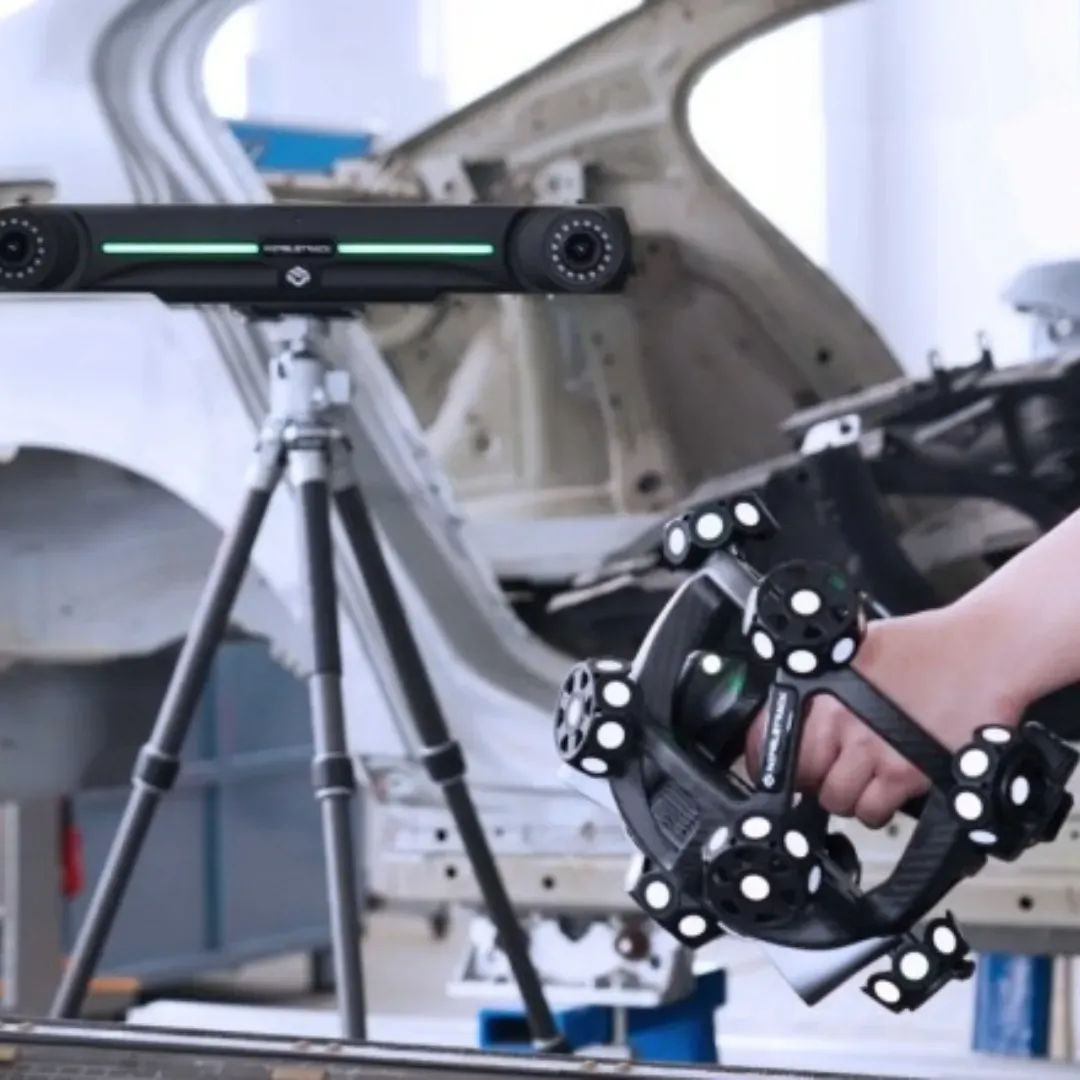

Reverse Engineering in Action: 3D Scanning & CAE Integration for Faster, Smarter Manufacturing

1. Understand the Workflow of Reverse Engineering

Learn how to capture real-world parts using 3D scanning technology, convert the data into accurate digital models, and prepare them for engineering use. The workflow covers every stage from data acquisition and processing to CAD reconstruction, providing a clear path from physical object to digital design.

2. CAE Integration for 3D Scanned Parts

Efficiently import scanned 3D geometry into FEA tools like Ansys Mechanical, prepare the model, and set it up for meshing and simulation.

3. Structural Integrity Assessment

Perform structural analysis to evaluate stress, deformation, and safety factors of the scanned model, ensuring the part meets performance requirements.

4. Design Improvement

Use FEA simulation results to identify weak points and guide design optimizations, leading to stronger, lighter, and more durable models.

Schedule Overview

8:30am - 9:00am : Registration

9:00am - 10:00am : From Arc to Ultrasonic: Advancing Welding Quality with Universal Tensile Testing Solutions

10:00am - 10:30am : Break + Consultation

10:30am - 11:30am : Calibration Matters: Building Trust, Safety & Compliance in Modern Industries

11:30am - 12:30am : Smart Material Solutions: From Elemental Analysis to RoHS & Sustainability Compliance

12:30pm - 2:00pm : Lunch break + Consultation

2:00pm - 3:00pm : Surface & Subsurface Precision: Elevating Quality with Vision Measurement & X-Ray Inspection

3:00pm - 4:00pm : Heat Treatment Reinvented: ECM Furnace Innovations for Multi-Process Efficiency & Quality

4:00pm - 4:15pm : Break

4:15pm - 5:15pm : Reverse Engineering in Action: 3D Scanning & CAE Integration for Faster, Smarter Manufacturing

5:15pm - 5:30 : Closing

Our Certifications & Recognition

Meet The Speakers

Barthelemy

ECM ASEAN General Manager

Dedicated professional with a strong passion for overseas business and heat treatment. He joined ECM Group in 2019 to lead business development in Korea, achieving success with major manufacturers. In 2022, he expanded his focus to Japan, and since 2023 he has also been driving ECM's growth in Southest Asia, including Thailand, Vietnam, Malaysia and Indonesia.

Alex Yap

Executive Director,

Obsnap Penang (Specialist 3D Scanner)

Sales Director of Obsnap Penang with over 15 years of experience in geometric dimensioning and measurement equipment. A Mechanical Engineering graduate, he previously gained valuable expertise at Mitutoyo and Hexagon, specializing in dimensional inspection and reverse engineering applications.

Joe Yen

Sales Director,

JS Analytical

Sales Director of JS Analytical with over 15 years’ experience in laboratory instruments and production equipment. As a certified Radiation Protection Officer (RPO), he specializes in compliance, safety, and sustainability solutions.

On Eng Heng

Technical Product Manager, HansVue Metrology

Co-Founder of Hansvue Metrology. Engineered in R&D, sharpened in quality control, and now leading in metrology, I help manufacturers elevate their quality standards through smart, reliable measurement technologies

Albert Wong

ANSYS Specialist

Holds a Master’s Degree in Mechanical Engineering from the University of Nottingham Malaysia (UNM) and has over 4 years of experience as an application engineer in CAE simulation. His expertise includes structural analysis and Computational Fluid Dynamics (CFD), with prior work in building ventilation, transient airflow, and aeroacoustics for the HVAC industry. He is also experienced in delivering both basic and advanced Ansys Mechanical training.

Samson Chong

Sales Director,

Victor Equipment Resources

Manufacturing

Founder of Victor Manufacturing under the Obsnap Group. With over 18 years of experience in material testing equipment, has guided industries from automotive to plastics and education in meeting international quality standards. Continues to drive innovation and practical solutions that make testing and compliance more efficient for manufacturers across Southeast Asia

Cheng Kam Seng

Head of Laboratory,

Obsnap Calibration, Obsnap Testing Services

Results-driven metrology and calibration professional with over 20 years of experience in laboratory management, ISO/IEC 17025 compliance, and quality assurance. Demonstrated expertise in calibration across temperature, torque, flow, pressure, mass, and force, both in laboratory and field environments. Recognized HRDC-certified trainer and accreditation signatory.

Explore Our Event Posters

Testimonials That Speak for Themselves

Real stories. Real results. Real impact.

Date : 5 February 2026 (Thursday)

Venue : Geno Hotel, Shah Alam

HQ Office

Obsnap Group of Companies,

29A, Jalan SS15/4C,

47500 Subang Jaya,

Selangor Darul Ehsan,

Malaysia.